|

|

|

||||||||||||||||||||

|

Infrastructure The energy infrastructure has grown over its history, but is still based on technology which was available around 200 years ago at the start of its development. That was the steam engine, which enabled the generation of electricity from coal. A gas network for coal gas (town gas) was added later which provided a much cleaner and more convenient means of heating than from coal. The current electrical infrastructure however is completely unsuitable for reconciling varying energy demand with increasingly varying energy supply. These difficulties can be overcome, but only at high cost in terms of both money and loss of efficiency. A revolution in our energy infrastructure is urgently needed |

||||||||||||||||||||

|

||||||||||||||||||||

|

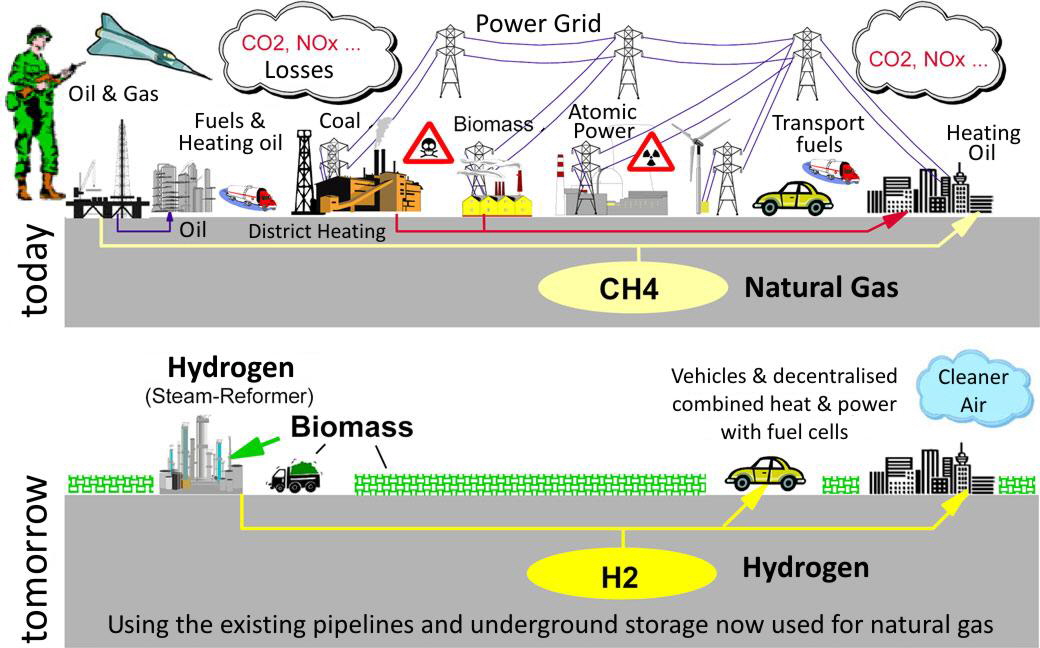

A hydrogen economy based on biomass compared to our legacy energy economy The lower diagram has been simplified by the use of biomass as it is the cheapest sustainable resource. As described in the concept, all types of long-term sustainable energy come not from fossil fuels of a past ages but from the living world of today. These diagrams shows how complex our current infrastructure is, and how simple it could look in future. |

||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

|

Power plants and high voltage transmission lines we see today |

||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

|

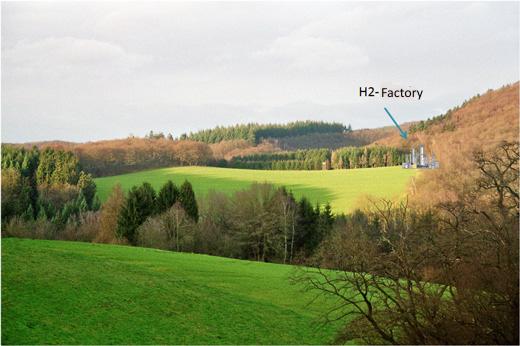

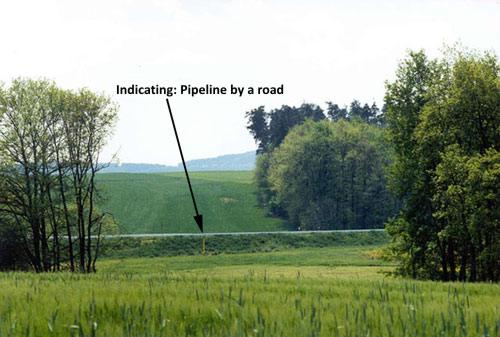

Hydrogen factories and gas pipelines we will could see in the future You have to be lucky to find a hydrogen factory, and very observant to notice the small yellow posts which mark the presence of a hydrogen pipeline. How much does the installation of a hydrogen economy cost? In the following sections, a rough calculation for the installation of a hydrogen economy in Germany is presented. Only the main components are quoted: the hydrogen factories and the extension of the gas pipe network to all premises (Note 1). As fuel cells will cost less than a domestic boiler or internal combustion engine with its power train, no premium nor discount is considered. |

|

|

One-off costs of around 40 billion Eros would allow the realisation of complete environmental and climate protection, and replacement of all nuclear and fossil-based fuels. That cost is small in comparison to what we would otherwise spend in the energy sector. For example:

The current concept of muddling along, results in costs over 10 years of around 3000 B€. The cost savings are 300 B€/yr. What a stimulus package that would be, when a sum similar to the annual German federal budget was flowing into the economy. The impression is often created in published opinion that renewable energy is the main cost factor. That is not correct. Using a true and objective analysis, it is clear that electricity generation from nuclear, lignite and coal fuels is already more expensive than producing electricity from the sun, wind and water. The expansion of renewable energy is therefore trend setting. The English economist Nicholas Stern has pointed out that for climate protection alone, the expansion of renewable energies is cheaper than doing nothing. Since a sustainable hydrogen economy makes the use of renewable energy more efficient and cost-effective, environment and climate protection would then cost no more.

Suitability of the Gas Network for Hydrogen NOT FULLY EDITED BEYOND THIS POINT 11/12/2015 As already described in the chapter Safety, the gas pipe network is technically suitable for hydrogen, if it is run with the same expertise as natural gas. It is possible to transport roughly the same amount of energy in a given pipe using hydrogen as using natural gas. The calorific value of hydrogen is lower than the calorific value for natural gas, but hydrogen flows more quickly through the pipe at a given pressure drop. (Note 2) Looking at the details, there are further restrictions. That is why it is important to differentiate between the type of peripheral equipment:

1. Compressed Natural Gas (CNG) Filling Stations The provision of CNG filling stations is viewed as an insurmountable barrier to the allowance of a hydrogen mix by the shareholders of the gas network. That originated as follows: at the turn of the century, the chairman of Ruhrgas, during a meeting of hydrogen experts from Nord-Rhein Westfalen, wanted to impress the hydrogen fans from the car industry by installing 2000 natural gas filling stations in Germany. In parallel, CNG was made free of tax, and a German standard was created (DIN 51624) which limits the proportion of hydrogen to 2% in CNG tanks. The Ruhrgas initiative already started working at around 1000 CNG filling stations. The hydrogen hype ended quickly (also for legal reasons). How much hydrogen the tank can withstand is not known. The DVGW set up a working as part of the NATURALHY project, which investigated the issue. A thin layer of non-precious metal, which can be applied either galvanically or by spraying would resolve the issue for a tiny cost. It has been accurately measured, according to the arguments to defend the natural gas network, that 0.2% of the car fleet justifies not changing the status quo of the gas pipe network. A different solution would be to remove the hydrogen before it reaches the filling station. By connecting a fuel cell upstream, the hydrogen part can be simply converted into electricity. The filling station then only receives less than 1% hydrogen as a proportion of delivered gas.

2. Heating systems In principle, all natural gas based heating systems can be converted to use hydrogen. Leaving the system settings the same, the heating capacity of both gases is the same. That comes from the Wobbe Index, which is roughly the same for both gases. The transition from town gas to natural gas was much more difficult, due to the difference in Wobbe Index. In this case, gas nozzles had to be replaced, and the (pre-compression) pressure changed. That all happened fairly quietly because the gas economy wanted it to happen. For hydrogen the will is absent. Even if the transition to hydrogen is simpler in principle, there are some special cases which need care. For a few very old boilers (more than 40 years old) a flame displacement was observed. A few brand new boilers have a pre-mixing chamber, for which the manufacturer (Bosch) limits the hydrogen content to 23%. The research team NATURALHY is currently looking for further exceptions. This issue seems important, because gas providers are allowed to change the type of gas used, if they guarantee that the customers systems work with the new gas. These system types are of no significance, if the transition is done in a technically intelligent manner.

Employing an immediate transition, the old boiler would be removed, and a fuel cell used, if the provision of hydrogen is guaranteed. If hydrogen cannot be guaranteed, then the fuel cell can be connected upstream of the boiler. If the case is changed from hydrogen to natural gas, the natural gas flows through the fuel cell without producing electricity and is burned in the boiler. If gas mixtures are present, the fuel cell is also deployed upstream of the old boiler. The fuel cell sucks the hydrogen down to 5% and generates electricity from it. The old boiler uses the remaining gas. In this way, the old boiler never sees more than 5% hydrogen in its natural gas. All boilers can cope with this. Customer billing in the case of mixed gas is more complex for the gas provider, as he must install a equipment to track the calorific value. For mixtures which change only gradually, this is fairly simple. Direct injection of hydrogen from fluctuating producers (wind, photovoltaics) is difficult or impossible. In these cases, hydrogen must be temporarily stored.

3. Gas turbines In this case the DVGW is unnecessarily putting forward a not-OK argument against hydrogen. The background is the specification of some manufacturers, that only 2-10% hydrogen is permitted, which is not proven, only claimed. The claims are that at a high proportion of hydrogen, the turbines need to be replaced. New hydrogen compatible turbines would cost 3.5 billion Euros. Setting aside the fact that muddling along will cost ten times that each year, a similar solution to point 1. and 2. is also applicable here, namely to add simple fuel cells upstream of the turbine, which limits the hydrogen content in the combustion chamber. In a hydrogen economy the issues are always regional. Trunk gas mains can still only transport natural gas. The changes are then only made by the regional gas provider (utility company). A natural gas power station can be connected to the trunk gas main and still run on natural gas. If the end customers of a town one day produce more electricity than the gas fired power station, there is a possible problem for the gas fired power station.

4. Cavern storage facilities Salt caverns are also sealed with respect to hydrogen. Because the sealing head of the cavern and the compressor must sustain sufficient alternating mechanical stress, a conversion requires a check on the materials used, which must be allowed to be used with hydrogen. It may be necessary to replace certain parts. When building new caverns (which is currently happening on a grand scale) the correct materials can be chosen. Such materials are in general not more expensive than currently used materials. In the final negotiations for the standard DVGW G 262 lobbyists reminded that with increased pressure and high hydrogen content, the element sulphur could drop out, and this could cause problems in the fittings and measurement equipment. They did not want to follow the proposal to remove the suphur instead of removing the hydrogen.

5. Porous reservoirs Spent gas and oil fields are used for the storage of natural gas. The stored gas is therefore usually contaminated. If the hydrogen content were raised, it would be converted into sulfurous compounds by bacteria, which could cause problems. Proof of these processes were not provided during the DVGW negotiations. This issue cannot be completely denied. Until this question is clarified, pure hydrogen storage in porous reservoirs should be avoided. They are also not needed.

6. Gas transport across borders As Europe still has no consistent legal framework for gas quality, making a statement is difficult. Earlier it was already mentioned that the hydrogen economy largely a matter for the utility companies. The international gas mains are therefore not needed at all. How urban areas are provisioned for from the countryside can be clarified on a case by case basis.

White paper: The DWGW published a study of network problems in 2013, which is only suitable for experts. Lay people often have difficulties to differentiate between scientific truth and defence strategies of the lobbyists.

Summary If the political will is there, to keep the lobbyists in their place, then a transition of the natural gas network to hydrogen is technically possible without much effort. Even the connection of all end users to the gas network would not overly strain the industry. |

|

last changed: 05.07.2014 |

||

|

|

||